Solutions

With the ecodos and ecoflow pump series in sanitary or hygienic design as well as the LEWA-developed mechatronically controlled intelldrive-technology, LEWA offers pumps that meet the high demands of pharmaceutical production without limitations:

- High metering accuracy

- Precise reproducibility for continuous processes

- Wide metering range

- Suitable for a wide variety of fluids

- Hermetically tight process chamber to save product and environment

- Short product holdup times and gentle conveying

- Depending on the option: CIP and SIP cleanability

- Hygienic and pharmaceutical designs

- FDA-compliant materials

- 3.1-material certificate

- QHD certificate

- Compliant with clean room requirements

LEWA metering systems excel primarily due to their fast, high-precision flow control.

Not only a mutual monitoring of pumps and flowmeters results from the pump characteristics stored in the process control, but also a plausibility check. This ensures high operating reliability and metering accuracy.

A further advantage is that the entire production process can be logged with no omissions, to pharmaceutical specifications. LEWA offers a large degree of practical experience during the selection of the suitable flowmeter and other components: All components match with each other and thus ensure a perfect function of the metering system.

Background

Process description

Fluids must be added to a substance mixture in pharmaceutical processes. This can also mean that the system must first prepare the product to be conveyed (e.g., blending, melting of salts, temperature control, dispersing, etc.). A custom-designed solution for the functionality of the system and adjustment of the individual components to the overall system is therefore required.

The actual conveying of the fluid must then be done under defined process conditions, e.g., definition of pressure and temperature, placing high demands on process control and thus on the complete system solution.

A stable process is possible with coordinated and individually programmed instrumentation and control technology and a control system. Using storable recipes in this system control, processes are carried out reliably and with maximum repeatability. Logging of the process progress and its results is indispensable for a reliable production in order to fullfil cGMP requirements.

The different user levels are only accessible to approved users. The system must have a design concept so that these can be qualified and validated. Therefored the guidelines according to CFR 21 part 11 are fulfilled.

The product made with the system must correspond to the specified quality guidelines of the pharmaceutical industry and conformity must be able to be verified at anytime.

Industries

Pumps and Systems for the Pharmaceuticals, Life Sciences and Biotechnology Industries

As the leading manufacturer of pumps and pump systems for the pharmaceutical, life sciences, and biotechnology industries, LEWA supports you during the development of complete solutions, which meet your process requirements exactly. Special expertise is required in the production of pharmaceuticals in order to ensure that legal requirements are met. Reliability when it comes to production, documentation, and validation are our top priorities.

More DetailsProducts

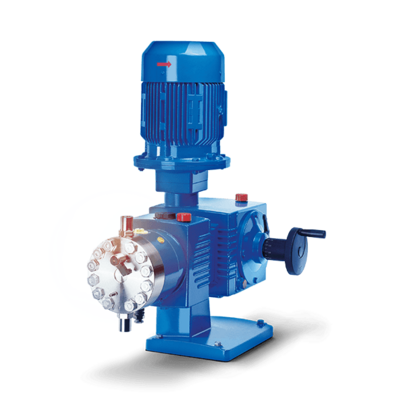

LEWA ecoflow®: The Leading Diaphragm Metering Pump for Precision Fluid Management

LEWA ecoflow: The Innovative Universal Metering Pump with DPS Diaphragm Protection. Trusted across all industries, this modular system pump excels in a wide range of applications. Experience unparalleled versatility and reliability with our ecoflow, the ultimate choice in metering pump technology.

More DetailsLEWA ecoflow®: Advanced Hygienic Diaphragm Metering Pumps for Sanitary Applications

Discover the LEWA ecoflow® in its hygienic version, designed for sanitary applications. This versatile metering pump maintains its renowned all-around performance while meeting the stringent hygienic standards required in pharmaceutical and food production industries.

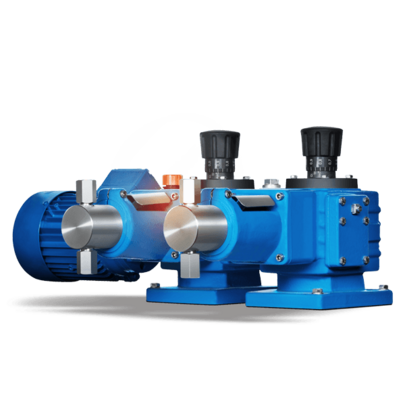

More DetailsLEWA ecoflow®: Your Solution for Advanced Packed Plunger Metering Pumps

Opt for the LEWA ecoflow packed plunger metering pump, a robust and reliable choice for hassle-free fluid metering. Available in multiple models to suit diverse processes, it's the metering pump trusted by industry leaders for consistent performance.

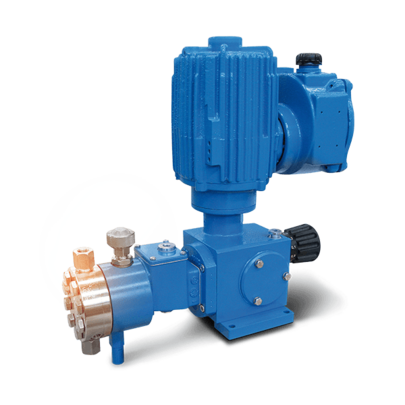

More DetailsLEWA ecodos®: Advanced Sanitary/Hygienic Diaphragm Metering Pumps for Precise Fluid Control

The LEWA ecodos is also offered in a sanitary/hygienic version, expertly meeting all operational standards for pharmaceutical and food production metering pumps.

More DetailsLEWA FC: High-Precision Laboratory Metering Pumps for Advanced Research Applications

Explore our precision metering pumps designed for micro-flow rates. The FC series, capable of handling pressures up to 400 bar, is tailor-made for laboratory and test center applications, offering unparalleled accuracy for small-scale fluid management.

More DetailsCustomer-Specific Metering, Mixing or Filling Systems from LEWA

Customer-specific batch/continuous systems for your production process. Metering, mixing, filling, separating, controlling temperature: We work with you to develop the ideal process-related sequence and produce the system that fits your production process – right up to the end product.

More DetailsCustomer-Specific Metering Systems from LEWA

Turnkey metering system in closed loop control with monitoring and plausibility testing equipment. Your individually configured metering system with an optimally designed pump for fluid metering in automated processes.

More DetailsLEWA triplex®: High-Pressure Homogenizing Process Pumps

The LEWA triplex homogenizing pump utilizes hermetic diaphragm technology, making it ideal for sensitive applications such as ready-to-drink products, infant food, nutraceuticals, and enteral nutrition. Designed to handle demanding fluids, it finds optimal use in the food, beverage, and pharmaceutical industries.

More Details