Solutions for extraction with supercritical fluids

LEWA metering pumps and process diaphragm pumps are very well suited for supercritical processes, since they meet all the relevant requirements.

Advantages of LEWA pumps:

- Hermetically tight

- Layout of high pressure pumps and their peripheral equipment for liquid gases (refrigeration equipment)

- Suitable for thin, non-lubricating fluids

- High operational reliability

- Low wear, almost no particle contamination due to minimal movement of pump head parts

- Easy to clean, food design available

- Hygienic design possible for pharmaceutical applications (Ra < 0.5 μm electro-polished, ASME BPPE, EHEDG)

- Installation in GMP areas/clean rooms

- Material conforms to FDA (GRAS: Generally Recognized As Safe)

- Installation possible in potentially explosive areas

- Optimum pump head material, for example Hastelloy, available for highly corrosive media

- Diverse connection geometries

- Custom valves possible

- Documentation on qualification/validation

- Tested for wafer cleaning (Fraunhofer IPA Tested Device®)

It must be noted that carbon dioxide must be in the liquid state to be pumped. This is not practical in the gaseous state due to its compressibility.

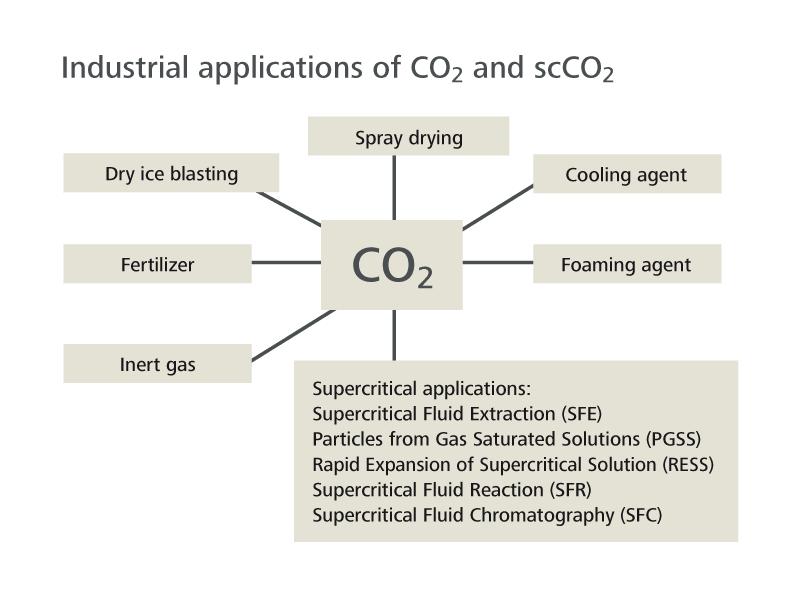

Areas of application: Extraction and other supercritical processes with LEWA pumps

LEWA metering pumps and process diaphragm pumps have been successfully used in the following processes:

- Extraction processes with supercritical CO2 (Supercritical Fluid Extraction SFE), such as decaffeination, degreasing, phytoextraction, as well as the extraction of oil seed, omega fish oil, flavors and spices

- Supercritical preparative liquid chromatography (Supercritical Fluid Chromatography SFC), as well as separation of optically active substances

- Supercritical Fluid Reactions SFR

- Particle formation (e. g., Particles from Gas Saturated Solutions PGSS), such as high-pressure spraying process for pulverizing greases, baked goods, aerogels, etc.

- Cleaning processes, e.g., process integrated separation of substances, such as pesticide removal (wool grease, lanolin)

- Cell breakdown, inactivation (gentle sterilization), cold pasteurization

- Dyeing of textile fibers (Dye is dissolved in scCO2, thus spreading more easily and penetrating deeper into textile fibers.).

- Supercritical CO2 as an additive in various recycling applications, such as removal of printing ink from paper mash in wastepaper recycling, devulcanization of rubber in waste tire recycling.

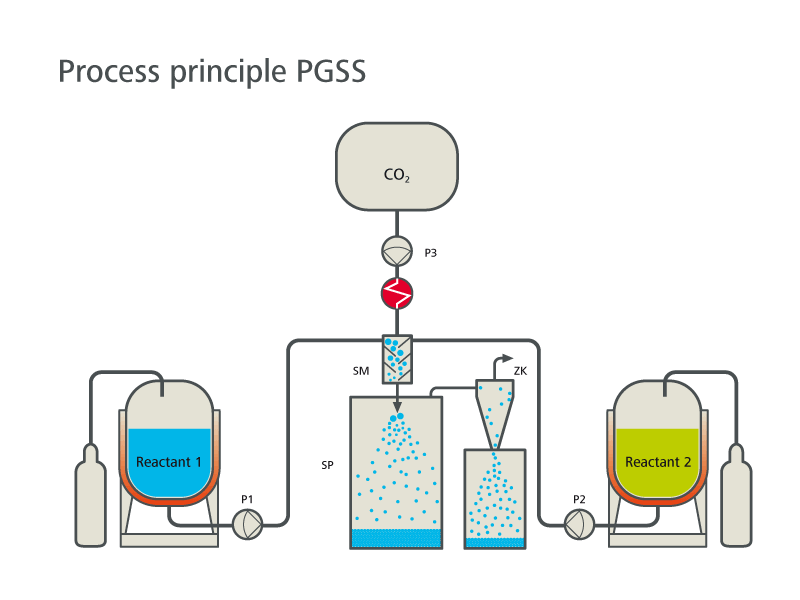

Principle of the PGSS process:

- Conditioning and melting two reactants 1 and 2

- Feed and compression with LEWA high pressure pumps P1, P2 and P3

- Mixing both reactants with supercritical fluid in a static mixer (SM)

- Decompression in a spray tower (SP) via a nozzle

- Droplet formation

- Cooling of droplets and particle formation

- Generation of powder in the spray tower with cyclone (ZK)

Background for supercritical fluids

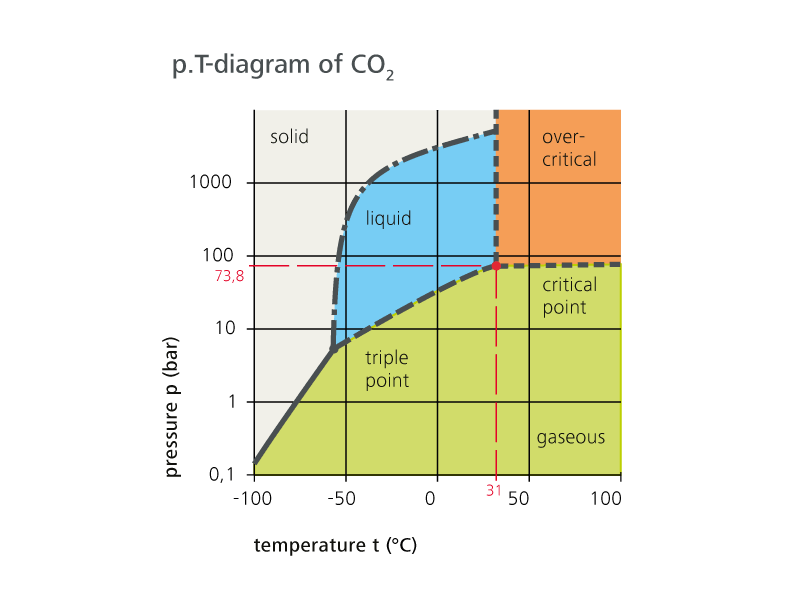

A supercritical fluid is a substance whose temperature and pressure are both over their critical point simultaneously (see diagram for CO2).

The critical temperature is the temperature over which the substance can no longer remain liquid, regardless of the pressure level.

Critical pressure is the pressure over which the substance can no longer form gas, regardless of the temperature.

Supercritical fluids have the density and good dissolving properties of fluids, as well as the viscosity, good compressibility, and diffusability of gases.

Due to their good mixing and mass transfer properties, they are classed as a fluid.

Important advantages of supercritical fluids:

- Safe, cost-effective, environmentally friendly, non-toxic

- They can replace organic solvents

- Good influence over slight changes in operating conditions

- Operating conditions under low temperature and pressure make them attractive for research and development in the pharmaceutical & biotechnology sector.

Selection criteria for the right supercritical fluid:

- Physical-chemical properties of the desired mixture

- Task of the solvent in the process in regards to solubility

- Specific application

- Safety, especially in regards to flammability, phase behavior under operating conditions

- Cost of the fluid

- Cost of the equipment

The most frequently used supercritical fluid is CO2.

Properties of carbon dioxide:

- Low critical temperature (31.1°C)

- Moderate critical pressure (73 bar)

- Non-flammable

- Non-toxic

- Mixable with organic solvents

- Recoverable after processing

- Diffuses faster than conventional fluid solvents

- GRAS status

- Approved by the FDA for use in food and pharmaceuticals

- Environmentally friendly

- Cost-effective

Industries

Pumps and Systems for the Production of Personal Care Products

Processes with strict quality and hygiene requirements, such as GMP or the need to avoid preservatives, require the right equipment. We support you in the selection and the design of hygienic components and systems for producing personal care products. Contact our experts and let us advise you – we will work with you to develop customized metering solutions for your process, such as for manufacturing personal care products.

More DetailsPumps and Systems for the Pharmaceuticals, Life Sciences and Biotechnology Industries

As the leading manufacturer of pumps and pump systems for the pharmaceutical, life sciences, and biotechnology industries, LEWA supports you during the development of complete solutions, which meet your process requirements exactly. Special expertise is required in the production of pharmaceuticals in order to ensure that legal requirements are met. Reliability when it comes to production, documentation, and validation are our top priorities.

More DetailsPumps and Systems for the Food and Beverage Industry

LEWA supports producers and plant construction companies in the food and beverage industries with pumps and systems for homogenization and dispersion, as well as for other processing operations in the food industry. We work with you to plan all the important process-related operations, such as conveying, metering, mixing, heating, and cooling so that you can process your raw product cost-effectively.

More DetailsProducts

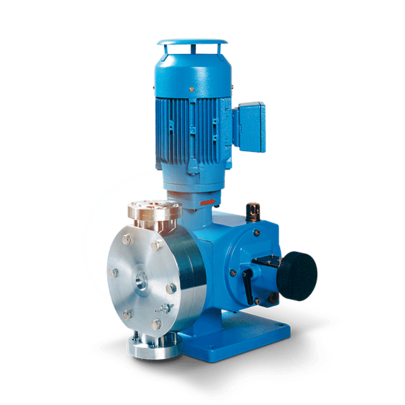

LEWA ecoflow®: The Leading Diaphragm Metering Pump for Precision Fluid Management

LEWA ecoflow: The Innovative Universal Metering Pump with DPS Diaphragm Protection. Trusted across all industries, this modular system pump excels in a wide range of applications. Experience unparalleled versatility and reliability with our ecoflow, the ultimate choice in metering pump technology.

More DetailsLEWA ecoflow®: Advanced Hygienic Diaphragm Metering Pumps for Sanitary Applications

Discover the LEWA ecoflow® in its hygienic version, designed for sanitary applications. This versatile metering pump maintains its renowned all-around performance while meeting the stringent hygienic standards required in pharmaceutical and food production industries.

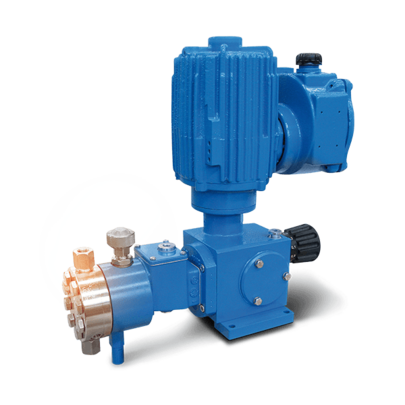

More DetailsLEWA ecodos®: Robust Mechanical Diaphragm Metering Pumps for Precision Dosing

The LEWA ecodos metering pump delivers absolute reliability, cost-efficiency, and adaptability for applications preferring non-diaphragm actuation. Trust in our proven modular system to design the optimal metering pump tailored to your specific needs.

More DetailsLEWA FC: High-Precision Laboratory Metering Pumps for Advanced Research Applications

Explore our precision metering pumps designed for micro-flow rates. The FC series, capable of handling pressures up to 400 bar, is tailor-made for laboratory and test center applications, offering unparalleled accuracy for small-scale fluid management.

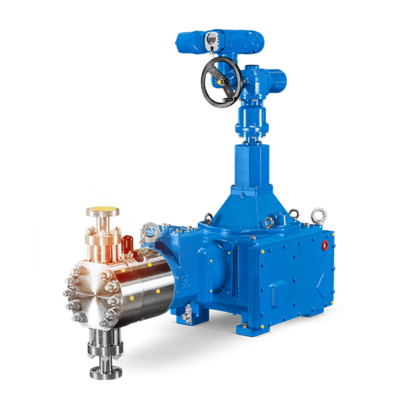

More DetailsLEWA ecoflow®: The Leading Process Pumps for High-Pressure Applications

The innovative ecoflow diaphragm process pump excels in high-pressure applications across industries including oil and gas, refinery, petrochemicals, pharmaceuticals, biotechnology, and food and beverage production.

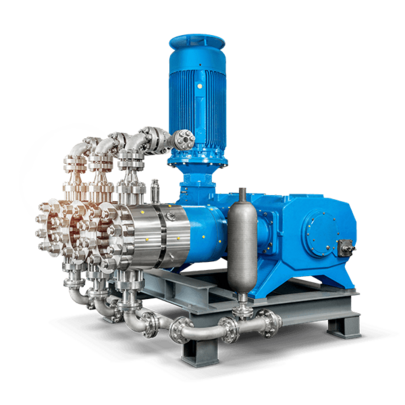

More DetailsLEWA triplex®: Compact Process Pumps for High-Pressure Applications

The LEWA triplex process diaphragm pump stands out as one of the world's most compact high-pressure pumps, ideal for installation in confined spaces. Renowned for its robustness, it has demonstrated exceptional performance across various high-pressure processes in multiple industries.

More DetailsCustomer-Specific Metering, Mixing or Filling Systems from LEWA

Customer-specific batch/continuous systems for your production process. Metering, mixing, filling, separating, controlling temperature: We work with you to develop the ideal process-related sequence and produce the system that fits your production process – right up to the end product.

More DetailsCustomer-Specific Metering Systems from LEWA

Turnkey metering system in closed loop control with monitoring and plausibility testing equipment. Your individually configured metering system with an optimally designed pump for fluid metering in automated processes.

More Details